Phone: +86-752-3198333

Email: sales@xcpcb.net

Website: en.xcpcb.net

Address: South of Lianfa Avenue, Yongqiao Industrial Park, Zhongkai High-tech Zone, Huizhou, Guangdong Province

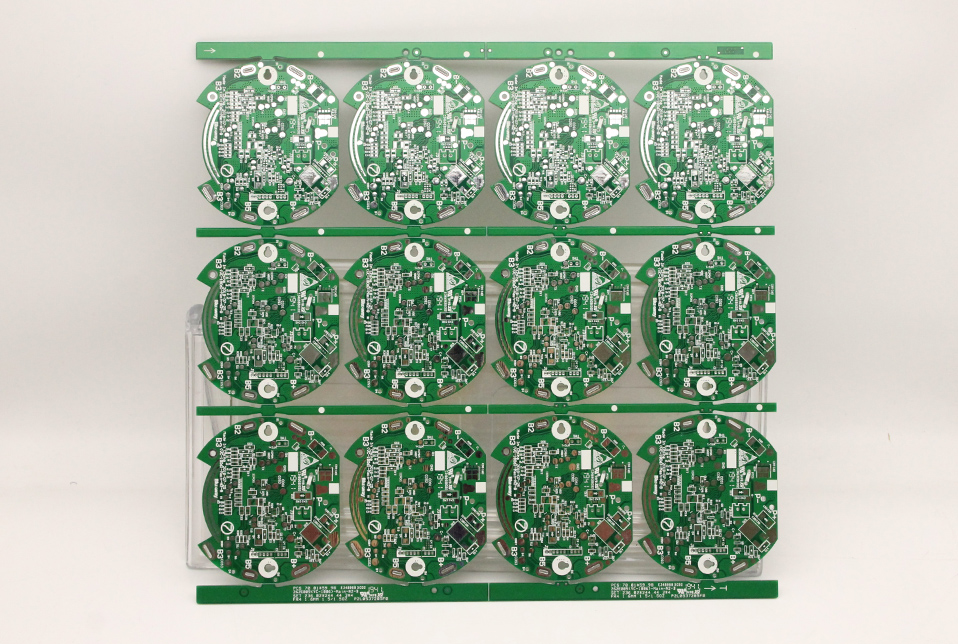

I don't know if you have found such a situation, most PCB boards are green, other color circuit boards are relatively rare. Why is this? Others say that black PCBs represent high-end, is that really the case?

PCB board-solder mask

First, let's get to know this green board.

The printed circuit board (PCB) is usually composed of pads, vias, solder masks, silk screen layers, copper wires, various components. Among them, the solder mask (solder mask) refers to the part of the printed circuit board to be coated with green oil. In fact, solder mask inks are only green, but also red, yellow, blue, purple, black, but green is the most common.

The role of solder mask:

(1) Prevent physical disconnection of conductor circuits;

(2) In the welding process, prevent short circuits caused by bridges;

(3) Solder only at the parts that must be soldered to avoid wasting solder;

(4) Reduce copper pollution to the welding tank;

(5) Prevent insulation deterioration corrosion caused by external environmental factors such as dust moisture;

(6) It has high insulation makes it possible to increase the density of circuits.

So why are most of the PCB boards green? The main reasons are as follows:

1. Green has less irritation to the eyes. Teachers have told us since childhood that green is good for the eyes, protects the eyes, resists fatigue. Production maintenance personnel are prone to eye fatigue when they stare at the PCB board for a long time do less damage to the eyes.

2. Low cost. Because green is the mainstream in the production process, the purchase amount of natural green paint will be larger, the purchase cost of green paint will be lower than other colors. At the same time, the use of the same color paint in mass production can also reduce the cost of changing lines.

3. When the board is soldered in SMT, it needs to go through tin patch the final AOI verification. These processes are learned to be optically positioned calibrated. The green background color has a good recognition effect on the instrument

Relevant webpage materials related resources on this site are sourced the Internet. If there is any infringement, please inform us quickly. We will delete it within 24 hours! Circuit board manufacturer